| Porositas yang jelas: | ≤ 22% | Kepadatan: | 2.2-2.4 g/cm3 |

|---|---|---|---|

| Barang: | bata alumina tinggi | Suhu pelunakan: | ≥1400 ℃ |

| Resistensi abrasi: | Tinggi | Suhu layanan: | Tinggi |

| Resistensi korosi: | Tinggi | Refraktorin di bawah beban: | ≥ 1520 ℃ |

| Aplikasi: | Lapisan tungku suhu tinggi | Suhu: | 1700-1800 ℃ |

| Perubahan linier permanen: | Rendah | Resistensi alkali: | Tinggi |

| Kekuatan CCS: | 45 | Resistensi asam: | Tinggi |

| Permukaan: | Mulus | ||

| Menyoroti: | bata tahan api alumina tinggi untuk tungku busur listrik,bata api silika alumina Al2O3 48-90%,bata tahan api alumina tinggi 230x114x65mm |

||

Kualitas tinggi 48-90% Al2O3 Alumina Silica Fire Brick 230*114*65mm High Alumina Refractory Bricks untuk Electric Arc Furnace Roof

Batu bata tahan api dengan aluminasi tinggi

Batu bata alumina tinggi mengacu pada produk tahan api aluminosilikat dengan kandungan aluminium oksida (Al2O3) lebih tinggi dari 48%.Hal ini terbentuk dengan membentuk dan mengkalsinasi bauksit atau bahan baku lainnya dengan kandungan alumina tinggiStabilitas termal tinggi dan ketahanan api di atas 1770 °C. Ini memiliki ketahanan slag yang baik dan digunakan untuk lapisan tungku listrik pembuatan baja, tungku kaca, tungku putar semen, dll.

Batu bata alumina berbahan tinggi lembut dan low creep tinggi adalah bahan tahan api kelas tinggi yang terbuat dari bauksit kelas khusus, corundum cair dan mullite cair.Produk ini memiliki keuntungan dari creep suhu tinggi kecil, ketahanan korosi yang kuat, stabilitas kejut termal yang baik, dll. Ini cocok untuk tungku tinggi panas ukuran besar dan menengah.

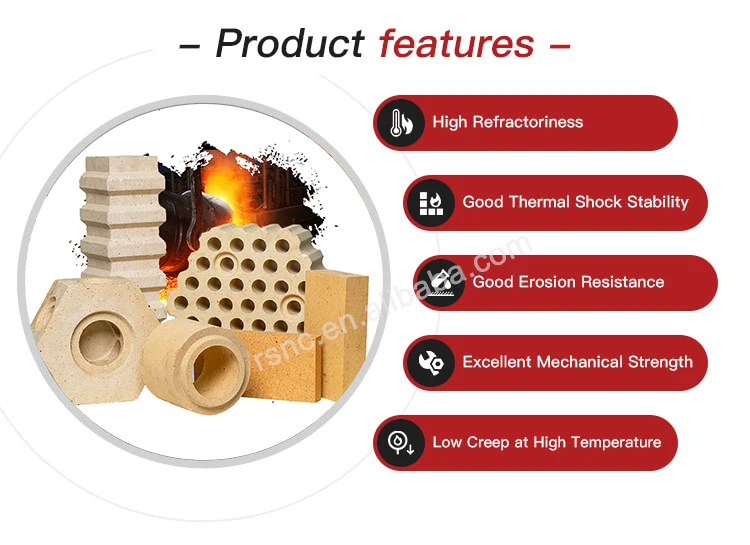

Keuntungan Batu bata tahan api dengan tinggi alumina

1. Refraktoritas tinggi;

2. Kekuatan suhu tinggi;

3. Stabilitas termal yang tinggi;

4. Neutral tahan api;

5. ketahanan yang baik terhadap korosi asam dan dasar slag;

6. Refraktoritas tinggi di bawah beban;

7. Resistensi tempur tinggi;

8. porositas yang rendah;

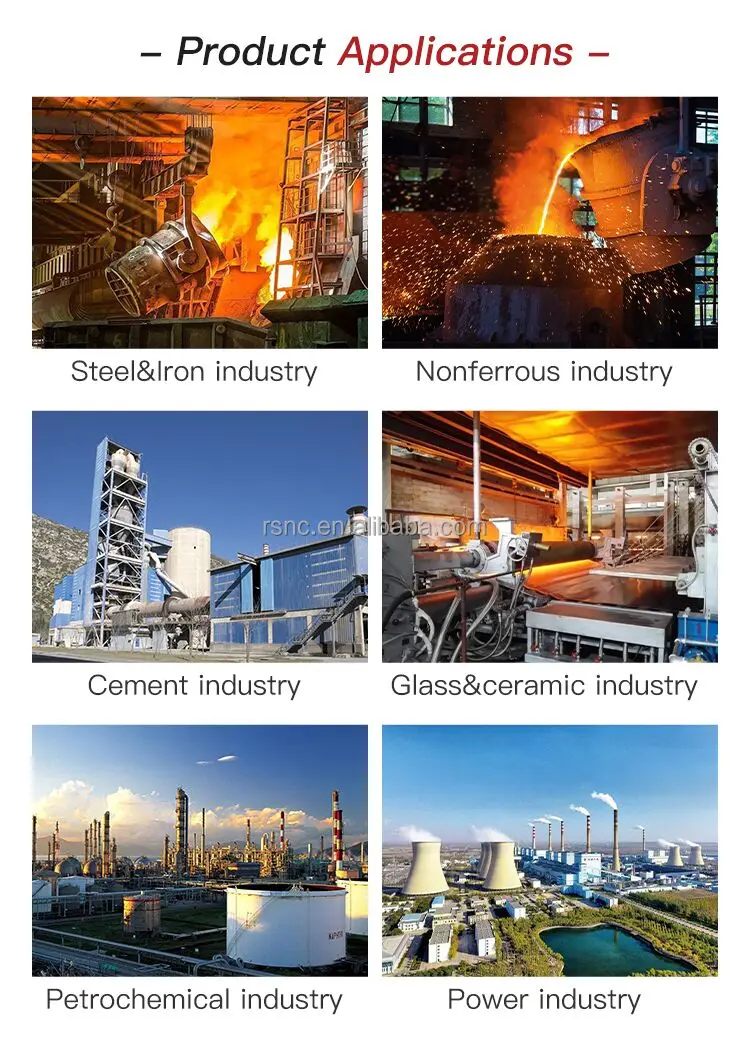

Aplikasi Batu bata tahan api dengan alumina tinggi

Sebagai bahan dasar dalam bidang teknologi suhu tinggi, batu bata alumina tinggi banyak digunakan dalam semen, bahan bangunan kaca, peleburan baja, petrokimia dan industri lainnya.Tungku industri suhu tinggi untuk batu bata alumina tinggi termasuk tungku tinggi, tungku tinggi panas, tungku listrik, tungku tinggi, tungku reverberasi dan lapisan tungku putar.batu bata soket untuk sistem tuang, batu bata nozzle, dll sesuai dengan kebutuhan tungku industri.

Indeks Fisik dan Kimia Batu bata tahan api Alumina Tinggi:

| Item/Kelas | Api Brick Tanah liat | Batu bata aluminium tinggi | ||||||

| SK-30 | SK-32 | SK-34 | SK-35 | SK-36 | SK-37 | SK-38 | SK-40 | |

| AL2O3% (≥) | 30 | 35 | 38 | 45 | 55 | 65 | 70 | 82 |

| Fe2O3% (≤ | 2.5 | 2.5 | 2 | 2 | 2 | 2 | 2 | 2 |

| Refraktoritas (SK) | 30 | 32 | 34 | 35 | 36 | 37 | 38 | 40 |

| Refractority Under Load, 0,2MPa, °C (≥) | 1250 | 1300 | 1360 | 1420 | 1450 | 1480 | 1530 | 1600 |

| Porositas Terlihat (%) | 22-26 | 20-24 | 20-22 | 18-20 | 20-23 | 20-23 | 20-22 | 18-20 |

| Densitas bulk (g/cm3) | 1.9-2.0 | 1.95-2.1 | 2.1-2.2 | 2.15-2.22 | 2.25-2.4 | 2.3-2.5 | 2.4-2.6 | 2.5-2.7 |

| Kekuatan penghancur dingin, MPa (≥) | 20 | 25 | 30 | 40 | 45 | 50 | 60 | 70 |

| Ukuran standar batu bata | |||||

| Splitstraight L×W×H(mm) |

Pembagian L×W×H(mm) |

ARCH L×W×H(mm) |

WEDGE L×W×H(mm) |

TILE L×W×H(mm) |

Bentuk lain |

| 230×114×65 | 230×114×25 | 230×114×65/45 | 230×114×65/45 | 230×230×38 | Keramik kunci |

| 230×114×75 | 230×114×32 | 230×114×65/55 | 230×114×65/55 | 230×230×50 | Batu bata miring |

| 230×114×37 | 230×114×75/45 | 220×114×75/45 | 230×230×65 | Sabun | |

| 230×114×50 | 230×114×75/55 | 220×114×75/55 | 230×230×75 | Pengontrol | |

| ≤10 | 230×114×75/65 | 220×114×75/65 | leher | ||

| Taper | |||||

| Aplikasi | Tungku baja, tungku kaca, tungku natrium silikat, tungku keramik shuttle, tungku putar semen, tungku tinggi, tungku listrik, tungku tinggi dan tungku reverberator. | ||||

| Kami juga dapat membuat batu bata sesuai dengan pelanggan' gambar dan persyaratan. | |||||

Kontak Person: Mr. Pika

Tel: 86-13838387996

Faks: 86-0371-56010932